Center of Excellence (CoE)

Center of Excellence for Youth Development Focusing on Women Empowerment Supported by Bharat Forge Pvt. Ltd.

About CoE

About Bharat Forge:

Bharat Forge Limited, a flagship company of the Kalyani Group, is a global leader in metal forging and one of the largest manufacturers of forged components for the automotive, aerospace, defense, energy, and industrial sectors. Headquartered in Pune, India, the company is renowned for its advanced manufacturing capabilities, cutting-edge technology, and strong research and development focus. With a presence in over 50 countries, Bharat Forge supplies high-performance components to major global OEMs and has a robust portfolio of innovations in lightweighting, electric mobility, and precision engineering. The company is committed to sustainability, digital transformation, and enhancing India's self-reliance in critical industries through initiatives in defense and green energy solutions. Bharat Forge emphasizes collaboration to drive India’s global economic rise. Aligning with Viksit Bharat’s vision Bharat Forge transitioned from traditional methods to AI-powered digitalization, revitalizing manufacturing, boosting exports, and expanding globally through R&D and automation.

About Centre of Excellence for Youth Development:

The Center of Excellence (CoE) at Vidya Pratishthan, Baramati, has been established through a joint effort between Bharat Forge Limited, Pune, and Vidya Pratishthan as part of Bharat Forge's CSR initiative. This centre aims to provide cutting-edge technological education and skill development opportunities to students in the Baramati region. The CoE comprises four advanced labs and an incubation centre equipped with high-end workstations and equipment, enabling students to transform their innovative ideas into prototypes and market-ready products.

The CoE promotes interdisciplinary project-based learning and offers mentorship from experts at Bharat Forge, reputed academic institutions, research centres, incubation hubs, in-house mentors, and alumni. It fosters an entrepreneurial ecosystem, helping students develop skills in emerging technologies such as IoT (Internet of Things), Machine Learning (ML), Computer Vision (CV), 3D printing, Augmented and Virtual Reality (AR & VR), Robotics, Electric Vehicles (EV), and Data Analytics (DA). This initiative not only enhances students' employability but also encourages entrepreneurship, especially in a rural setting like Baramati.

Since its establishment on 11th March 2023, the CoE has played a crucial role in nurturing young talent, including encouraging the participation of female students in core industrial sectors like manufacturing. By bridging the gap between academia and industry, the CoE is shaping the next generation of innovators, problem-solvers, and entrepreneurs while contributing to job creation and rural development.

Vision:

To be a leading centre of excellence that empowers students with cutting-edge technological skills, fosters innovation and entrepreneurship, and bridges academia with industry to drive inclusive and sustainable development.

Mission:

To equip students with practical knowledge and hands-on experience in emerging technologies.

To create an ecosystem that encourages students to transform innovative ideas into viable prototypes and market-ready products.

To bridge the gap between academic learning and industrial applications by offering mentorship from industry experts, reputed institutions, and research centres.

To develop job-ready skills and promote interdisciplinary project-based learning to increase students’ career prospects.

To encourage the participation of female students and individuals from rural areas in high-tech domains, fostering diversity and contributing to rural development.

Objectives:

1. To integrate resources, learning, and talent in cutting-edge technologies in one place.

2. To nurture cutting-edge technology-based innovations, IPRs, and startups.

3. To develop skilled human resources to serve the needs of industry and society with more focus on women empowerment.

4. To provide need-based technology training to researchers, entrepreneurs, and the industry.

5. To ensure the self-sustainability of CoE by identifying new revenue generation opportunities through Training, IPR, and consultancy work

CoE Team

Name:

Designation:

Qualification:

Research Interests:

Email Id:

Dr. Jyoti Rangole

Associate Professor

B.E.(Electronics), M.Tech.(Digital System),Ph.D.

Modeling and simulation, Data analytics, Underwater acoustics, Digital Image Processing

jyoti.rangole@vpkbiet.org

Brief Profile :

Jyoti Rangole received her Bachelor's degree in Electronics Engineering from Shivaji University in year 2001. She received M.Tech. (Digital System) in year 2009 from College of Engineering, Pune. She has completed her Ph.D. in the area of Underwater Signal Processing at SRTMUN, Nanded in Sep. 2020. Her research center is Shri Guru Govind Singh Engineering and Technology, Nanded. During her 15+ years tenure at VPKBIET, Baramati, she has worked in different capacities like Head of Department, IEEE, WIE, Coordinator, PG Coordinator, Project Coordinator, Department NBA coordinator, Institute Entrepreneurship Development Cell coordinator.

Jyoti teaches Signals and Systems, Digital Image Processing, Microcontrollers, Embedded System and RTOS, Mini Project and Seminar. Her areas of interest include Underwater Acoustic Signal/Image Processing, Biomedical Image Processing, Automation in Agriculture and Sericulture Industries and Product Development.

She has on her credit two research projects funded by BCUD SPPU (Project Duration 2012-2014, 2016-2018). She has presented her research contributions in various International Conferences and journals. She has filed three patents in year 2019-2020. She is the university level winner of Avishkar 2017 in Agriculture and Animal Husbandry, Teacher Category. She is actively involved in attracting the research grants from various national funding agencies including AICTE, DST, and RGSTC, etc. She guides the students in product design and development and helps them to register their startups. Two of her students have registered their startup in year 2020.

Vidwan Profile: https://vpkbiet.irins.org/profile/264005

Teaching Areas :

Subjects taught: Microprocessor, Microcontrollers, Embedded System Design, Advanced Processors, Signals and Systems, Digital Image Processing, Network Theory, Mini project. Research Projects Completed/Ongoing :

Working as Principal Investigator for project titled, Side Scan SONAR Image Analysis: An application to sediment classification, funded by SPPU, BCUD, Pune.

Grant received: Rs.1, 40,000/- (Project Duration: Year 2016-2018)

Worked as Principal Investigator for project titled, Automatic Counting of Silkworm Eggs Using Image Processing, funded by SPPU, BCUD, Pune. Grant received: Rs. 2, 31,000/-(Project Duration: Year 2012-2014)

Publication in Peer-Reviewed National and International Journals and Book Chapters:

Statistical characterization of an underwater channel in a tropical shallow freshwater lake system, Advances in Intelligent Systems and Computing, Springer book series, 2019 (Scopus Indexed).A computationally-efficient model for determining sound speed in shallow tropical freshwater systems, with field validation, Journal of Lake and Reservoirs Research and Management, Wiley Publication, 2019 (Scopus Indexed).

Validation of model-based techniques for characterization of surface sediment at Khadakwasala Lake with field data, Indian Journal of Geophysical Union, 2019 (UGC-CARE).

Automatic silkworm egg counting mechanism for sericulture, Advances in Intelligent Systems and Computing Volume 216, 2014, pp. 121-128 Springer India, 2016 (Scopus Indexed).

International Conferences :

Echo signal analysis for underwater sediment classification in tropical regions," OCEANS 2016 MTS/IEEE Monterey, Monterey, CA, 2016, pp. 1-5, doi: 10.1109/OCEANS.2016.7761370. Precise estimation of sound velocity profile and its impact on sediment classification in the tropical shallow freshwater reservoirs," 2015 IEEE Underwater Technology (UT), Chennai, 2015, pp. 1-6, doi: 10.1109/UT.2015.7108227.

Sediment classification using side scan-sonar imagery, 12th Western Pacific Acoustic Conference, Singapore, pp. 445-448, 2015, ISBN: 978-981-09-7961-4.

Vision system for automatic counting of silkworm eggs," International Conference on Information Communication and Embedded Systems (ICICES2014), Chennai, 2014, pp. 1-5, doi: 10.1109/ICICES.2014.7034036.

Detection of leukemia in microscopic images using image processing," 2014 International Conference on Communication and Signal Processing, Melmaruvathur, 2014, pp. 255-259, doi: 10.1109/ICCSP.2014.6949840.

Implementation of image processing algorithms on FPGA, International Journal Technology World 2010, Malaysia. 16.Edge detection for real time image processing using FPGA, International Conference on Science and Technology, Dhule, 2010.

Patents Filed: No. of patents filed: 03 :

Product Development :

Student Startups Registered :

Awards/Achievements :

Summer Faculty Research Fellow at IIT, Delhi from 29 May 2012 to 12 July 2012 under the guidance of Dr. Sumantra Dutta Roy.

Stood second in the Ph.D. entrance test conducted by Babasaheb Ambedkar Marathwada University.

University level winner in Avishkar 2017 competition in Agriculture and Animal Husbandry (Teacher Category- SPPU, Pune).

Second prize in Rotary Water Olympiad 2017 organized by Rotary and SPPU, Pune for the research work in Sediment classification using acoustic techniques.

Presented research work at Water Olympiad Competition organized by Rotary and University of Pune, 2019.

Outcome of Students’ Project Guided :

Name:

Designation:

Qualification:

Research Interests:

Email Id:

Dr. Vipin Gawande

Assistant Professor

B.E (Mech. Engg.), M.Tech[Heat Power Engg], Ph.D (V.N.I.T, Nagpur)

Computational Fluid Dynamics, Heat Transfer and Solar Energy

vipin.gawande@vpkbiet.org

Brief Profile :

Dr. Vipin B. Gawande has completed his B.E in Mechanical Engineering from Government College of Engineering, Amravati in 2004. Later he worked as a CFD Engineer at Mechwell Industry, Nashik. After scoring 90.02 percentile in GATE examination, he joined M. Tech course in Heat Power Engineering at Visvesvaraya National Institute of Technology (V.N.I.T) Nagpur. He is also a recipient of Ph.D Degree from V.N.I.T Nagpur. He has total 06 years of experience, including teaching, research and industry. He has also completed a minor project sponsored by Department of Science and Technology (D.S.T), Government of India.

Vidwan Profile: https://vpkbiet.irins.org/profile/263462

Recognition :

Recognized reviewer of- 1) Elsevier’s “Applied Thermal Engineering” journal.

2) Elsevier’s “Alexandria Engineering Journal”.

3) Elsevier’s “International Journal of Heat and Mass Transfer”

Patent:-

One patent published (Patent application No. 201621021852)

Publications

Peer-Reviewed Journal

Publications:

Gawande, Vipin B., A. S. Dhoble, and D. B. Zodpe. "Effect of roughness geometries on heat transfer enhancement in solar thermal systems–A review." Renewable and Sustainable Energy Reviews 32 (2014): 347-378. (Elsevier, Impact Factor- 9.184)

Gawande, Vipin B., A. S. Dhoble, and D. B. Zodpe. "CFD analysis to study effect of circular vortex generator placed in inlet section to investigate heat transfer aspects of solar air heater." The Scientific World Journal 2014 (2014). (Publisher – Hindawi, Impact Factor- 1.220)

Gawande, Vipin B Dhoble, A. S., Zodpe, D. B., & Chamoli, S. "Experimental and CFD-based thermal performance prediction of solar air heater provided with right-angle triangular rib as artificial roughness." Journal of the Brazilian Society of Mechanical Sciences and Engineering 38 (2) (2016): 551-579. (Publisher – Springer, Impact Factor- 1.627)

Gawande, V. B., Dhoble, A. S., Zodpe, D. B., & Chamoli, S.. Experimental and CFD-based thermal performance prediction of solar air heater provided with chamfered square rib as artificial roughness. Journal of the Brazilian Society of Mechanical Sciences and Engineering, 38(2) (2016), 643-663. (Publisher – Springer, Impact Factor- 1.627)

Gawande, V. B., Dhoble, A. S., Zodpe, D. B., & Chamoli, S. "A review of CFD methodology used in literature for predicting thermo-hydraulic performance of a roughened solar air heater."Renewable and Sustainable Energy Reviews 54 (2016): 550-605. (Publisher – Elsevier, Impact Factor- 9.184)

Gawande, V. B., Dhoble, A. S., Zodpe, D. B., & Chamoli, S. Experimental and CFD based thermo hydraulic performance evaluation of a solar air heater with reverse L-shaped rib roughness on absorber plate. Solar Energy (2016). (Publisher – Elsevier, Impact Factor- 4.374).

Gawande, V. B., Dhoble, A. S., Zodpe, D. B., & Chamoli, S. Analytical approach for evaluation of thermal hydraulic performance of roughened solar air heater, Case studies in thermal engineering 8 (2016) 19-31. (Publisher – Elsevier, Cite Score-3.05)

Wadhawan, Amol, A. S. Dhoble, and V. B. Gawande. "Analysis of the effects of use of thermal energy storage device (TESD) in solar air heater." Alexandria Engineering Journal (2017). (Publisher – Elsevier, Cite Score-2.81)

Gawande, V. B., A. S. Dhoble, D. B. Zodpe, and S. G. Fale. "Thermal performance evaluation of solar air heater using combined square and equilateral triangular rib roughness." Australian Journal of Mechanical Engineering (2018): 1-11. (Publisher Taylor and Francis)

Gawande, Vipin B., A. S. Dhoble, D. B. Zodpe, and Chidanand Mangrulkar. "A comparative analysis of thermo-hydraulic performance of a roughened solar air heater using various rib shapes." Australian Journal of Mechanical Engineering (2018): 1-20. (Publisher Taylor and Francis)

Chidanand K. Mangrulkar, Ashwinkumar S. Dhoble, Sunil Chamoli, Ashutosh Gupta, Vipin B. Gawande. Recent advancement in heat transfer and fluid flow characteristics in cross flow heat exchangers. Renewable and Sustainable Energy Reviews 113 (2019) 109-220. (Publisher –Elsevier-Impact Factor-9.184)

Conference Proceedings:

Gawande V.B., Ramgadia Abhishek, Saha Arun. Numerical study of flow and heat transfer in wavy channel. Proceedings of the 20th National and 9th International ISHMT-ASME heat and mass transfer conference, Jauary-4-6-2010, Mumbai-India.

Gawande V.B., Zodpe, D.B., Pawar G.P. Flow analysis of flue gases in ESP inlet duct using CFD. Proceeding of the 4th international conference on advances in Mechanical Engineering, September 23-25, 2010,. S.V.National institute of technology, Surat, Gujrat. India.

Gawande V.B., Zodpe D.B., Kachale Dhanajay. Application of CFD in various fields of engineering. MIPFEST-08, 22 January, 2008, Koneru Lakshmaiah College of engineering, green fields, Vaddeswaram, A.P, India.

Sachin Bichitkar, Prasad Buddiyal, Siddhant Chavan, Ajinkya Kulkarni, Dr. V. B. Gawande. “CFD analysis of wind turbine with different flange angles”. 1st International Conference on Applied Mechanical Engineering Research at N.I.T Warangal, Telangana during 2-4th May-2019.

Name:

Designation:

Qualification:

Research Interests:

Email Id:

Mrs. Komal Gaikwad

Assistant Professor

M. E. (Computer Engineering)

Data Science, Internet of Things

komal.gaikwad@vpkbiet.org

Brief Profile :

Mrs. Komal Gaikwad received her B.E. degree in 2012 from Vidya Pratishthan’s Kamalnayan Bajaj Institute of Engineering and Technology (formerly, VPCOE), Baramati. In 2015, she completed M.E. in Computer Engineering from JSPM’s JSCOE, Pune. She has completed 6 months training and certification on “IBM Data Science” course. She has qualified GATE in Computer Engineering in 2018. Since 2007, she has served at the VPKBIET and currently, she is Assistant Professor at AIDS department. She has taught Software Engineering, Data Structures, Internet of Things, Human Computer Interaction, Object Oriented Programming and related labs.

Publications:

Komal Jadhav, Sharmila Shinde, “Prioritization of Re-executable Test Cases in Model Based Environment- A Survey”, International Journal of Computer Science and Information Technologies, Journal, Journal ISSN Number: 0975-9646, year 2015

Komal Jadhav, Sharmila Shinde, “Prioritization of Re-executable Test Cases of Activity Diagram in Regression Testing Using Model Based Environment”, International Journal on Recent and Innovation Trends in Computing and Communication, Journal ISSN Number: 2321-8169, year 2015

Komal Jadhav, “Prioritization of Re-Executable Test Cases in Model Based Environment”, Conference at MET Bhujbal Knowledge City, METs Institute of Engineering, Nashik, cPGCON-2015 Date: 13th and 14th March 2015

Methodology for Project Execution:

Project Proposal Call for FE to BE Students:

Announcement: A call for project proposals will be made by the CoE to First Year (FE) to Bachelor of Engineering (BE) students. The call will include detailed guidelines on the types of projects sought, eligibility criteria, and submission procedures. Submission: Students are encouraged to submit their project proposals that align with the CoE's focus areas (such as IoT, Robotics, AI, 3D Printing, etc.). Proposals should outline the project objectives, methodologies, expected outcomes, and required resources.

Project Proposal Presentation at CoE:

Selection Process: After the submission deadline, students will be invited to present their proposals at the CoE. The CoE Selection Committee consisting of faculty members and domain experts will evaluate the proposals based on innovation, feasibility, and relevance to the technological advancements at the CoE.

Presentation Format: Students will be required to deliver a structured presentation, followed by a Q&A session. The committee will assess the clarity of objectives, project timeline, and the students' understanding of the topic.

Allotment of Facilities:

Resource Allocation: Once a project is selected, the CoE will allocate the necessary facilities and equipment (e.g., 3D printers, IoT kits, robotics workstations, etc.) to the students based on the requirements of their proposed projects.

Infrastructure Support: The CoE will ensure that the selected students have access to state-of-the-art infrastructure such as laboratories, hardware, and software tools for project execution.

Allotment of Mentors from Institute/Department:

Mentor Assignment: Each project will be assigned a faculty mentor from the relevant department (e.g., Electrical, Mechanical, Computer Science). The mentors will guide the students in refining their project ideas, overseeing project execution, and providing expert advice on technical and theoretical aspects. Collaboration with Industry Experts: In some cases, external industry mentors from Bharat Forge or affiliated companies may also be assigned to the projects, especially for specialized areas such as Electric Vehicles or Advanced Robotics.

Progress Reviews at Regular Intervals:

Scheduled Reviews: Progress will be monitored through regular review meetings at specified intervals (e.g., bi-weekly or monthly). Students will present the status of their project, including work completed, challenges faced, and solutions implemented. Feedback and Evaluation: During these reviews, mentors and the CoE team will provide constructive feedback to guide students in overcoming obstacles and improving their projects. The progress will be assessed based on milestones outlined in the project proposal.

Adjustments: Based on the feedback, adjustments will be made to project timelines, scope, or methodologies as required to ensure the successful completion of the project.

Noteworthy Projects (AY-2023-24)

Design of Sugarcane Bud Detection and Cutting System using Deep Learning

The agriculture sector acts as a strategic job in the economic growth of the country. The automation of various processes in agriculture is essential to increase yield production and the same applies to sugarcane cultivation. Sugarcane is the principal crop in India and many countries. The most crucial process in sugarcane cultivation is the identification of healthy buds. To produce the largest sugarcane, yield the traditional methods of sugarcane plantation find limitations as these methods are costly, time-consuming, and won 100% plantation. Identification of healthy sugarcane buds is essential during the plantation process to assure maximum yield. Further, present systems available in the market provide limited automation with a relatively higher cost making it exorbitant for the small and medium-scale farmers.

Egg Hatchery Machine

Poultry meat is rich in protein, nutrition and essential for the human growth and development. It has great demand from all levels of society having diverse background. The chicken meat food safety begins with the hatching process at the farm. To meet high demand of the poultry meat, hatcheries need to maximize chick production in sustainable manner. The main objective of the project is to design an automated egg hatcher machine for Chickens, Ducks, Goose Birds, Pigeon and Quail for increased production. The temperature, humidity and oxygen level in the incubator is monitored by taking input from temperature, oxygen and humidity sensors. In future the system for fertility detection of the eggs could be explored. The system is scalable based on the egg capacity.

Controlled Wheelchair

A wheelchair, generally used by the handicap peoples, is operated manually. It requires human efforts to rotate various parts of the wheelchair. An attempt has been made by the student of Final Year Mechanical Engineering, to develop an automated wheelchair for these peoples. For identification of the hand gestures the Accelerometer MPU6050 was used which measures the angle of tilt in two axes to read the output of MPU6050, Arduino Uno was used, which provide the required movement of the wheelchair as per the hand gestures. The wheelchair will be useful for the reduction of human efforts to run the wheelchair and will reduce their dependency on other family members.

Autonomous Delivery Robot

An autonomous delivery robot was developed by making use of sensors, navigational systems, and artificial intelligence (AI) algorithms. Various parts of this robot were manufactured on 3D printer available in the CoE. M8N GPS module was used to track the accurate location using satellite signals. Google Maps is used to plot the waypoints to establish the robot’s optimal path. The robot will be useful in the situations where human interference can be minimized. In case of medical emergency situations, like COVID, these types of robots could be used for delivery of medicines to the patients to avoid the infection.

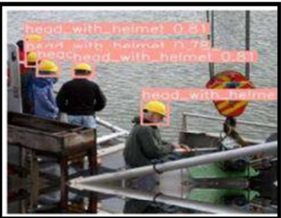

Smart Helmet Detection System: An IoT- Based Solution for Enhanced Safety

The project makes use of Arduino Uno, pressure sensor/IR sensor, Magnetic sensor, sender, and receiver Wi-Fi module for the project. The project is beneficial to identify the availability of helmet for the workers and thus to reduce the accidents on the working area. The Team members for this project are Mr. Abhishek R. Raut, Ms. Kalyani K. Paliwal, Ms. Vaishnavi D. Damare, Mr. Rishi N. Nashikkar and Ms. Sakshi S. Shiraskar.

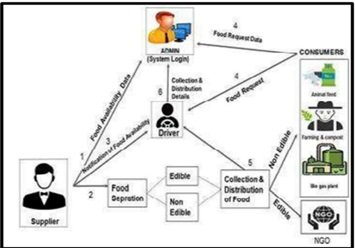

Effective Food Waste Management

This project aims at development of a mobile application for food waste collection and effective recycling of domestic waste.

Features of the application are:

The team members for this project are Mr. Kunal Sapkal, Ms.Shivhari Kotule, Ms.Gauri Maid

FOOD CREATING MACHINE

A group of Bachelor of Engineering (B.E.) students from Department of Mechanical Engineering, associated with our Centre of Excellence, embarked on an ambitious project to design, and develop a food-creating machine. This project aimed to address issues of food preparation efficiency, nutritional customization, and convenience, leveraging advanced engineering principles and technologies. The resulting machine can produce a variety of food items using a combination of automated processes and innovative food science.

Projects Outcomes

| Outcomes | Nos. |

| Patents | 01 (Granted), 02 (Under Examination) |

| Copyrights | 01 (Published) |

| Publications (Journals and Conferences) | 01 (IEEE Conference) |

| Participations (Project Competitions, hackathons etc) | 03 |

| Awards/Prizes | 02 |

| MoUs | 01 |

Activities@CoE

| Activity Title | Activity Type | Date of Activity | No. of Participants |

| IPR and IP Management for Start Ups | Workshop | 25th July-2024 | 150 |

| 3D Printing | Short Term Training Programs (STTP) | 15th Jan-2024 | 20 |

| Artificial Intelligence | Short Term Training Programs (STTP) | 12-14th Jan-2024 | 60 |

| Internet of things | Short Term Training Programs (STTP) | 11th Jan-2024 | 60 |

| Robotics and Automation | Short Term Training Programs (STTP) | 10th Jan-2024 | 60 |

| Call for an Incubation Centre | - | 8th Jan-2024 | 60 |

| 3D Printing | Workshop | 26th Dec-2023 | 50 |

| 3D Printing | Workshop | 22nd Dec-2023 | 50 |

| Robotics and Automation | Workshop | 20th Dec-2023 | 55 |

| Arduino Programming and Simulations | Workshop | 21st -22nd Oct-2023 | 36 |

| Start up Ecosystem India and Globe | Expert Lecture | 18th Oct-2023 | 60 |

| How to Write and Publish Research Paper in Reputed Journals | Expert Lecture | 13th Oct-2023 | 100 |

| Smart India Internal Hackathon -SIH-2023 | Competition | 26th Sept-2023 | 300 |

| Role of Soft Aspects in Technological Development | Expert Lecture | 15th Sept-2023 | 60 |

| Patent Drafting Session | Expert Lecture | 11th Sept-2023 | 58 |

| 3D Printing Technology | Short Term Training Programs (STTP) | 28th March-2023 | 51 |

Internships@CoE

The Bharat Forge Supported Centre of Excellence at Vidya Pratishthan has announced a call for an internship program aimed at Third Year Engineering students. The internship will have a duration of 4 weeks, and students can participate in the program after their regular academic sessions. The internship is structured to offer learning through shadowing and/or project-based work. Additionally, training will be provided to students based on their individual needs and the requirements of the projects they are involved in.

The internship covers the following domains:This program offers students an excellent opportunity to gain hands-on experience in cutting-edge technologies and contribute to projects while enhancing their skills in these rapidly evolving fields.

Industry/Society and CoE Interaction

Project-01

The Centre of Excellence (CoE) has received a request from Fine Dies and Moulds Pvt. Ltd., located in Pune, to produce 15 units of a 3D printed tool holder. This report outlines the process from the receipt of the request to the final production, including design considerations, material selection, and quality assurance procedures. The project was coordinated by Dr. Vipin B. Gawande.

Project 02: Service to community project

The Centre of Excellence (CoE) has undertaken an innovative project to design a leopard-patterned belt using advanced 3D printing technology. This project aims to demonstrate the capabilities of 3D printing in producing complex, customizable fashion accessories. The use of a leopard pattern adds an element of style and uniqueness, showcasing the versatility and precision of modern 3D printing methods. The project was provided by the Deputy Conservator of Forests Ghod Project Forest Division, Junnar, Dist. Pune. The designed was carried out by Simusoft Technologies, Pune and the model was printed on 3D printer available at our Centre.

Outreach Programs from CoE

The Centre of Excellence (CoE) regularly participated in a CSR meeting where its initiatives and activities were presented to Baba Kalyani, Chairman of Bharat Forge. The meeting focused on showcasing the CoE’s impact, detailing its contributions to youth development, skill enhancement, and entrepreneurship.

The Centre of Excellence (CoE) represented by the team participated in the "Yuwashakti Career Shibhir" organized by the Department of Skills, Employment, Entrepreneurship, and Innovation, Government of Maharashtra. The event aimed to empower and guide students and young professionals by providing insights into career opportunities, skill development, and entrepreneurship.

During the session, CoE shared its resources and programs related to technical skill development, entrepreneurship, and industry-academia collaboration. Emphasizing on hands-on training, project-based learning, and internships, CoE also highlighted the various opportunities available for students to enhance their technical skills in emerging technologies such as IoT, AI, Robotics, 3D Printing, and more.

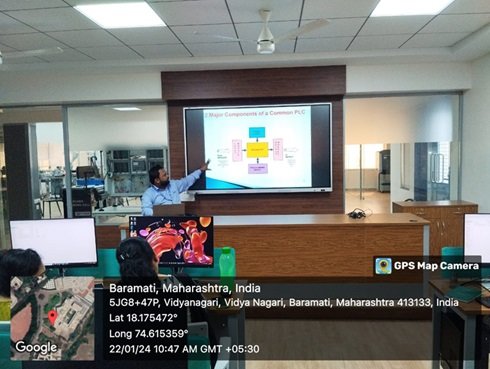

Center of Excellence in Digital Manufacturing and Robotic Automation(CoEDMRA)

About CoEDMRA

CoEDMRA was inaugurated on 23rd December 2023 at the auspicious hands of Shri. Deepak Chhabria, Chairman, Finolex J-Power Systems Ltd and Shri. Sharadchandraji Pawar, Honorable Member of Parliament (Rajya Sabha) in the presence of Shri. Prataprao Pawar,Chairman, Sakal Media Group and Dr. Ajit Jaokar, Professor, Oxford University, UK.

Objectives:

Center of Excellence in Digital Manufacturing and Automation, referred as CoEDMRA or simply CoE, is a dedicated facility established in Vidya Pratisthan’s educational campus that focuses on research, development, training, and collaboration in the fields of digital manufacturing, Industry 4.0, automation, artificial intelligence, robotics, and related technologies.

The CoE acts as a catalyst, bridging the gap between academia and industry by equipping students with the skills and knowledge needed to excel in modern manufacturing practices.

The facilities available at CoEDMRA is utilized for the following purposes:

Conducting advanced training courses in the field of Robotics, Automation, and Industry 4.0 etc. for the students to enhance their skills in these emerging areas.

For conducting training sessions for Industry peoples.

Conducting visit and training sessions for students and faculties from the nearby technical institutes and all VP’s technical institutes as per their requests.

Vision:

To be a leading centre of excellence that empowers students with cutting-edge technological skills, fosters innovation and entrepreneurship, and bridges academia with industry to drive inclusive and sustainable development.

Mission:

To equip students with practical knowledge and hands-on experience in emerging technologies.

To create an ecosystem that encourages students to transform innovative ideas into viable prototypes and market-ready products.

To bridge the gap between academic learning and industrial applications by offering mentorship from industry experts, reputed institutions, and research centres.

To develop job-ready skills and promote interdisciplinary project-based learning to increase students’ career prospects.

To encourage the participation of female students and individuals from rural areas in high-tech domains, fostering diversity and contributing to rural development.

Objectives:

1. To integrate resources, learning, and talent in cutting-edge technologies in one place.

2. To nurture cutting-edge technology-based innovations, IPRs, and startups.

3. To develop skilled human resources to serve the needs of industry and society with more focus on women empowerment.

4. To provide need-based technology training to researchers, entrepreneurs, and the industry.

5. To ensure the self-sustainability of CoE by identifying new revenue generation opportunities through Training, IPR, and consultancy work

CoE Team

Name:

Designation:

Qualification:

Research Interests:

Email Id:

Mrs. Prachi Kale

Assistant Professor

B.E.(Mechanical Engg.),M.E.(Design Engg.), Ph.D. Pursuing

Tool Design, Stress analysis and optimization.

prachi.kale@vpkbiet.org

Brief Profile :

Prachi D. Kale has completed her Master degree in Mechanical Design from Walchand Institute of Technology ,Solapur in 2012 and B.E. Mechanical sadnwich from All India Shree Shivaji Memorial society’s college of Engg. Pune University in 2005. Currently she is pursuing her PhD. from G H Raisoni College of Engineering and Management, Wagholi, Pune.Prachi has total 18 + years of experience.She has worked for 3 yrs in Mechanical industries with Drann Engg.Pvt.Ltd. and Fine Dies and Moulds Pvt.Ltd.Bhosari.She was working as Process Planning and Quality Incharge.She has 15 + years of teaching experience dealing with subjects like Engineering graphics, Engineering Mechanics, Basic Mechanical Engineering,Theory of Machines and Mechanisms, Dynamics of Machinery,Metrology and Quality control, Industrial engineering and Technology Management for Undergraduates and Analysis and Synthesis of Mechanisms, Industrial Tribology, Product life Cycle Managements for postgraduate level.

Presently, she is working as Center head for Vidya Pratishthan’s Centre of Excellence in Digital Manufacturing & Robotic Automation and had also schouldered responsibilities such as PG Coordinator, Sr.Supervisor online exam, Technical paper presentation coordinator, Unit test coordinator, class coordinator, F.E. subject coordinator etc. She has also attended ISTE workshop on Engineering Mechanics, Thermodynamics and syllabus implementation workshops on Engineering Graphics and Theory of Machines.

Vidwan Profile: https://vpkbiet.irins.org/profile/280781

Grants/Funding Recevied:

Under Research Proposal Scheme (RPS) of BCUD SPPU, Pune, she has recieved the funding of Rs. 1,70,000 /-. This research work is related to optimization of suspension system .

Publications :

Kale Prachi D., Kakandikar G.M., Naik S.B. "Heat Sheild Formability Analysis Using Taguchi Design of Experiments," TASE ,Science Road International Publication,2012.

Sawant Priyanka, Kale P.D., "Force and Friction Analysis of Disc brake of two Wheeler", International Journal of Multidisciplinary Educational Research, ISSN : 2277-7881, IF-2.735, V:5.16, March 2014.

Khalate R.N., Kale P.D.,"Fabrication and Static Analysis of Mono Composite Leaf Spring" International Journal of Recent Scientific Research, vol 7, issue 1, January 2016.

Name:

Designation:

Qualification:

Research Interests:

Email Id:

Mr. Dadasaheb Rupanwar

Assistant Professor

B.E.(Production Engg.), M.Tech.(Design Engg.,IIT-Bombay)

Mechatronics, Robotics, FEM and programming tools like MATLAB, control system, MEMS.

dadasaheb.rupnawar@vpkbiet.org

Brief Profile :

Prof. Dadasaheb Rupanvar has completed his B.E. in Production Engineering from Pune

University in 2001. He has more than five years of teaching research and industries

experience.Dadasaheb has worked as a 'Trainee Engineer'

in Excellent Engineering Industries Pvt. Ltd. Sangli from March 2002 to November 2002.

Then he has worked as a lecturer in Mechanical Engineering Department of Jawaharlal Nehru College Of Engineering, Aurangabad during the academic year of 2006-07. Dadasaheb has also worked as a lecturer in Production Engineering Department at Bharati Vidyapeeth College Of Engineering Pune during the academic year 2007-08 . Dadasaheb then joined Indian Institute Of Technology Bombay, Mumbai as a 'Research Assistant' and completed his M.Tech. in Mechanical Design Engineering from IIT BOMBAY, Mumbai in 2011. His area of research and interest is MEMS, Mechatronics and Robotics.

Presently, as an Asst. Professor, Dadasaheb is dealing with the subjects like Hydraulics and Pneumatics,Mechatronics, Advanced Mechanical Vibrations etc. as per the curriculum of Savitribai Phule Pune University.He has succesfully completed the training programme on "Industrial Automation with Electro-hydraulics and Electro-pneumatics" from Advanced Training Institute, Mumbai in June 2012.

Vidwan Profile: https://vpkbiet.irins.org/profile/280060

Publications :

Dadasaheb Rupanwar, Suryakant Kumbhar, "Design and analysis of composite coil spring to

optimize strain energy by using FEA", in VSRD International Journal of Mechanical, Civil,

Automobile and Production Engineering, Volume V, Issue VII, July 15.

Dadasaheb Rupanwar, Satish Choudhar, Ashok kalgunde, "Cost - Effective Solution for Twist Free Chassis Design of Three Wheeler Vehicles", in International Journal of Innovations in Engineering and Technology (IJIET), Volume 5, Issue 1, February 2015.

Name:

Designation:

Qualification:

Research Interests:

Email Id:

Mr. Mandar More

Assistant Professor

B.E.(Mech. Engg), M.Tech.(Robotics & Automation)

Robotics, Automation, Mechatronics, ROS, IIOT, AIML, Digital Twin.

mandar.more@vpkbiet.org

Brief Profile :

Mr. Mandar More received his B.E. Degree in Mechanical Engineering in 2023 from Vidya Pratishthan’s Kamalnayan Bajaj Institute of Engineering and Technology, Baramati affiliated to Pune University (presently SPPU) Maharashtra. He received his M-Tech. degree in the area of Mechanical Engineering, Specialization in Robotics and Automation in 2025 from Vidya Pratishthan’s College of Engineering, Baramati affiliated to Pune University (presently SPPU) Maharashtra.Mr. Mandar More’s interests span advanced interdisciplinary domains such as Robotics, Automation, Mechatronics, ROS, IIoT, AI/ML, Digital Twin, Simulation, Embedded Systems, 3D Printing, and Drone Technology. He specializes in robotic arms, SCARA and 6-axis robots, PLC-HMI systems, Arduino, Raspberry Pi, SLAM-based AGVs, AI-integrated control systems, and UAVs. His expertise includes simulation tools like Plant Simulation, FlexSim, Visual Components, and RoboDK. His diverse projects—ranging from SLAM-enabled AGVs and AI bots to drone systems and solar tracking devices—highlight his practical approach to innovation and automation.

Name:

Designation:

Qualification:

Email Id:

Mr. Sudam Kadhane

Technical Staff

ITI, NCTVT

sudam.kadhane@vpkbiet.org

Name:

Designation:

Qualification:

Email Id:

Mr. Shrikant Jathar

Trainer

ITI

shrikant.jathar@vpkbiet.org

Equipments and Facilities

| Section/Laboratory | Equipment/ Software |

| Simulation Lab | Automation Studio Simulation Software |

|---|---|

| SSCNC CNC Simulator | |

| RoboDK Simulation Software | |

| Witness Horizon Simulation Software | |

| Mechatronics Section | PLC & HMI Training Kit-Basic |

| PLC & HMI Training Kit-Advanced | |

| Computer Controlled Electropneumatic Kit with PLC & IIOT | |

| Computer Controlled Electrohydraulic Kit with Proportional Valve, PLC & IIOT | |

| IIOT and PLC Based Sensor Training Kit | |

| Robotics Section | Industrial Robocell-6 axes Articulated Handling cell |

| IIOT Based Smart Factory with 6 axis Articulated Robot | |

| SCARA Robot Training Cell | |

| Digital Manufacturing Section | CNC Lathe |

| CNC Vertical Machining Center | |

| Stratasys F170 3D printer |

Training Programs Conducted

| Details of Students Training Program Conducted | ||||

| Batch | Duration (Days) | No. of Participants | Start Date | End Date |

| TE Electrical (2024-25) | 3 | 48 | 09-10-2024 | 11-10-2024 |

| TE Mech (CNC Training) | 1 | 39 | 05-10-2024 | 05-10-2024 |

| SE Mech (2024-25) | 3 | 48 | 04-10-2024 | 06-10-2024 |

| BE ENTC (2024-25 Batch-2) | 3 | 29 | 01-10-2024 | 03-10-2024 |

| Pravara College BE Robotics & Automation | 1 | 21 | 24-09-2024 | 24-09-2024 |

| TE Mech (2024-25) | 3 | 30 | 18-09-2024 | 20-09-2024 |

| BE Mech (2024-25) | 3 | 40 | 10-09-2024 | 12-09-2024 |

| SY ENTC (2024-25) | 3 | 71 | 28-08-2024 | 30-08-2024 |

| BE ENTC (2024-25 Batch-1) | 2 Weeks(2 Hrs/day) | 22 | 12-08-2024 | 26-08-2024 |

| SE ENTC (2023-24) | 4 | 33 | 13-04-2024 | 16-04-2024 |

| TE Mech (2024) + BE Mech (2024) | 4 | 30 | 08-04-2024 | 12-04-2024 |

| Faculty Training Program Conducted | ||||

| Batch | Duration (Days) | No. of Participants | Start Date | End Date |

| V. P. Polytechnic, Indapur | 3 | 5 | 02/01/2025 | 04/01/2025 |

| Faculties from Walchand College of Engineering | 3 | 23 | 19/12/2024 | 21/12/2024 |

| Faculties from VPKBIET, Baramati | 4 | 18 | 1/4/2024 | 4/4/2024 |

| Faculties from VPKBIET, Baramati | 4 | 18 | 7/2/2024 | 10/2/2024 |

| Faculties from VPKBIET, Baramati | 3 | 19 | 23/01/2024 | 25/01/2024 |

| Faculties from VPKBIET, Baramati | 1 | 19 | 22/01/2024 | 22/01/2024 |

| Industry People Training Programme Conducted | ||||

| Batch | Duration (Days) | No. of Participants | Start Date | End Date |

| Accurate Gauging and Instruments Pvt. Ltd. | 3 | 11 | 12/03/2024 | 14/03/2024 |

Components Developed/Manufactured at CoE

| Name of Product | Quantity | System Used | Date | Remark | Amount |

| Ajit dada Pawar Model | 1 | 3D Printer | - | Kept in CoE | NA |

| Drone ESC Mount | 4 | 3D Printer | - | Mounted on Drone | NA |

| Drone Spray Holder | 4 | 3D Printer | - | Mounted on Drone | NA |

| Drone Spray Tank | 1 | 3D Printer | - | Mounted on Drone | NA |

| Drone Spray Tank | 2 | 3D Printer | - | Mounted on Drone | NA |

| Drone Base Mount | 2 | 3D Printer | - | Mounted on Drone | NA |

| Drone Battery Mount | 2 | 3D Printer | - | Mounted on Drone | NA |

| Drone Camera Mount | Multiple | 3D Printer | - | Mounted on Drone | NA |

| Hinge Pins | Multiple | 3D Printer | - | Kept in CoE | NA |

| Collar Hinge Prototypes | Multiple | 3D Printer | - | Kept in CoE | NA |

| Collar Belts | Multiple | 3D Printer | - | Kept in CoE | NA |

| Drone Remote Protectors | 1 | 3D Printer | - | Mounted on Drone | NA |

| Drone Servo Mount | 2 | 3D Printer | - | Mounted on Drone | NA |

| Drone Servo Mount | 2 | 3D Printer | - | Mounted on Drone | NA |

| Drone Flower Dropping Bucket | 1 | 3D Printer | - | Mounted on Drone | NA |

| SimuSoft Logo | 1 | 3D Printer | - | Kept in CoE | NA |

| VP Logo | Multiple | 3D Printer | - | Kept in CoE | NA |

| CoEDMRA Logo | 1 | 3D Printer | - | Kept in CoE | NA |

| Shri. Sharadchandraji Pawar | 1 | 3D Printer | - | Kept in CoE | NA |

| Ram Mandir Model | 1 | 3D Printer | - | Kept in CoE | NA |

| Ganapati Murti | 2 | 3D Printer | - | Kept in CoE | NA |

| Big Chess Pieces | 3 | CNC/VMC | - | In Stock | NA |

| Big Chess Pieces | 3 | CNC/VMC | - | In Stock | NA |

| Small Chess Pieces | 1 | CNC/VMC | 03/01/2025 | Sold | 15000 |

| Small Chess Pieces | 3 | CNC/VMC | 28/10/24 | Sold | 45000 |

| Rajmudra | 1 | CNC/VMC | 16/5/24 | Sold | 2000 |

| Flag Stand | 1 | CNC/VMC | 16/5/24 | Sold | 2000 |

| Small Chess Pieces | 1 | CNC/VMC | 16/5/24 | Sold | 11000 |

Eminent Visitors to the CoEDMRA

| Name of Guest/Group | Description |

| YASHDA (17/12/2024) | Yashwantrao Chavan Academy of Development Administration |

| Dr. Suresh Ukrande & Team (14/12/224) | K. J. Somaiya COE, Mumbai |

| Ms. Ashwini Deodeshmukh & Mr. Prafull More (27/11/2024) | Godrej India Ltd, Vikhroli, Mumbai. |

| Deepak Kalshetti | President, Auto Division, Kalyani Technoforge |

| Honeywell Team | Honeywell Automation India Ltd. |

| D. V. Kulkarni (30/06/24) | Analogic Automation Pvt. Ltd. Pune |

| John Nickell (30/04/24) | British Deputy High Commissioner, Mumbai |

| Advait Ghaisas (23/03/24) | Mondelez India Foods Pvt. Ltd, Pune. |

| Girinath Deshpande (23/03/24) | Mondelez India Foods Pvt. Ltd, Pune. |

| P. T. Deotale (03/03/24) | Joint Director, DVET, RO, CSN. |

| Ramakant B. Bhavsar (07/02/24) | Jt. Director, Regional Office, Vocational Education & Training, Pune. |

| Prashant S. Mishra (18/01/24) | Founder and Chief Executive Officer (CEO) of Click2Cloud® Inc. |

Center of Excellence for MATLAB for Research Via Enhanced Learnings(MARVEL)

Vision:

Mission:

Objectives:

Benefits:

Activities:

MATLAB Ability Test

As a part of MATLAB Competition fair, we have initiated MATLAB Ability Test – 2019 as a “Pilot Test” to test fundamental knowledge of MATLAB & Simulink and for showcasing MATLAB Skills. The test was scheduled on Monday, July 22nd, 2019.

Session on Machine learning & IoT

Mr. Suraj Gawande (Engineer (Technical Support-Mathworks) DesignTech Systems Ltd.) visited VPKBIET on July 26th, 2019 for the Interaction and awareness session on Machine Learning and Internet of things using MATLAB. The purpose of this visit was special interaction in the view of support, questionsanswers, troubleshooting the queries and spreading awareness of Machine Learning and Internet of things using MATLAB at VPKBIET. This time we have focused the interaction for students and faculty of all departments .

Interaction with faculties of Electrical and Mechanical Engineering on MATLAB Utilization

Mr. Pawankumar Fakatkar (Education Technical Evangelist, MathWorks, India) visited VPKBIET on July 30th, 2019 for the Interaction and awareness session on MATLAB. The purpose of this visit was special interaction in the view of support, questionsanswers, troubleshooting the queries and spreading awareness of MATLAB usage at VPKBIET. This time we have focused the interaction for Electrical & Mechanical Engineering Departments (students and faculties).

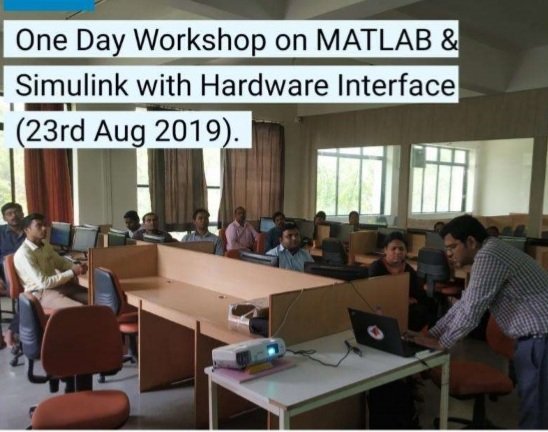

One Day Workshop on MATLAB & Simulink with Hardware Interface.

Arranged one-day workshop on MATLAB & Simulink with hardware interface on 23rd Aug 2019 at VPKBIET, Baramati

Workshop Organizer: Shashank Biradar,

CoE-MARVEL Coordinator & MATLAB Admin, VPKBIET, Baramati.

Resource Person: Mr. Pawankumar Fakatkar,

Education Technical Evangelist, MathWorks, India.

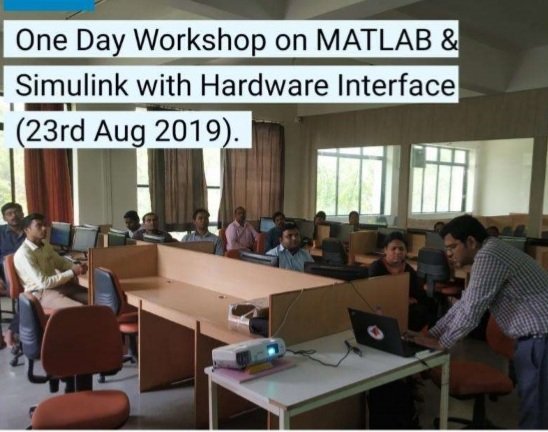

One Day Workshop on MATLAB & Simulink with Hardware Interface.

Arranged one-day workshop on MATLAB & Simulink with hardware interface on 23rd Aug 2019 at VPKBIET, Baramati

Workshop Organizer: Shashank Biradar,

CoE-MARVEL Coordinator & MATLAB Admin, VPKBIET, Baramati.

Resource Person: Mr. Pawankumar Fakatkar,

Education Technical Evangelist, MathWorks, India.

Testimonial for User Success Story on MATLAB Cover Page!!

The session was arranged on MATLAB R2019b: Installation, Awareness

and Features is arranged for all faculty. Regarding new release of MATLAB

2019b, speaker has covered basics of installations, new updates and

enhanced features of the toolboxes and MAOTS and incorporation of

MATLAB is regular curriculum and teaching-learning process.

Details of the program are as follows:

Speaker: Mr. Suraj Gawande, DesignTechsys, Pune.

MATLAB Toolbox for Workshop (15th Dec 2019.)

As per the directives of Principal sir, all the faculty were informed to give the choices of the MATLAB toolboxes of their interest. Out of the selected toolboxes, one toolbox (preferably 1st Priority), they need to study thoroughly, and they need to conduct full day workshop on toolbox (6-7 Hrs.) for faculty and students in the next semester for 2-3 times.

MATLAB Toolbox workshop action plan and Self-paced courses certification schedule. (15th Dec 2019)

After allocation of MATLAB Toolbox/es to faculty members as per their choices. With reference to the allotment, the respective faculty were expected to conduct workshops on these MATLAB Toolbox/es for faculty and students in the vacations and next semester.

Curriculum-MATLAB Mapping (February 21st, 2020)

As per the directives of Hon. Principal sir, all faculty requested to work on the Curriculum-MATLAB Mapping for better utilization of MATLAB for easement to understand the concepts for the students through day to day teaching for their respective courses. All faculty are requested to find the correlation of the MATLAB-Simulink Toolboxes with the curricular subjects, for the subjects that you taught last semester and teaching this semester, with reference to MATLAB Details (used & Proposed), Use of MATLAB (Implemented & Proposed) & Outcomes (Achieved & Proposed).

Online lecture on “Introduction to Deep Learning using MATLAB”

In view of the pandemic situation and nationwide lockdown due to COVID 19, we have arranged Online lecture on Introduction to deep learning using MATLAB exclusively for faculty and Students of VPKBIET on April 1st, 2020 through Cisco WebEx application. Interested students and faculty have attended the session. The overall feedback from participants for the said meeting was great.

Online lecture on “Audio Toolbox using MATLAB”

In view of the pandemic situation and nationwide lockdown due to COVID 19, we have arranged Online lecture on Audio Toolbox using MATLAB exclusively for faculty and Students of VPKBIET on April 10th, 2020 through gotowebinar application. Interested students and faculty have attended the session. The overall feedback from participants for the said meeting was great.

Online lecture on “MATLAB/Simulink in Mechanical Engineering”

In view of the pandemic situation and nationwide lockdown due to COVID19, we have arranged Online lecture on MATLAB/Simulink in Mechanical Engineering for Mechanical Engineering faculty of VPKBIET on April 23rd, 2020 through Cisco WebEx application. Interested faculty have attended the session.